Description

Classes of fire resistance

- Single leaf: E 60, EI2 60 , EI2 90, REI 120.

- Double leaf: EI2 60 , EI2 90, REI 120.

Quality first

- Fully galvanized door, including the “hidden” parts

- Made of “Sendzimir” processed hot-galvanized sheet metal

- Corrosion protection also provided along cut edges of the metal sheets

- Painted with epoxy-polyester thermoset powders in a 180 degrees (Celsius) oven

- Substantial paint layer (70 microns plus)

- Optimal corrosion resistance demonstrated by 500 hour salt-fog test

- Unaffected by severe climate changes, demonstrated by 2000 hours with +60° to -10° cycles at 75% humidity

- Finishing with high-quality aesthetics

- Orange skin anti-scratch structured paint

- Customizable with wide selection of RAL colors

Practicality of use

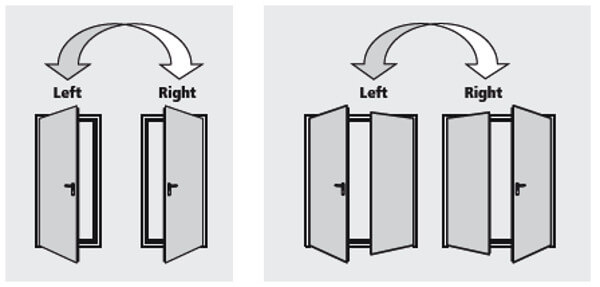

- Door reversibility (except in combination with certain optional accessories)

- Indication of door opening direction not necessary

- Reduction of stock for retailers

- Simplifies choices for end-customers

- Multiple installation methods for each door

- Type approvals for anchors for mortar fixing or expansion screws

Conformity to standards

- In-house Ninz R&D with specialized testing equipment

- Fire testing in accordance with UNI 9723 and EN 1634-1

- Mechanical testing for the CE marking of accessories

- CE marked door accessories studied and sized to meet standard European requirements

- Careful selection of materials and manufacturing methods

- Strict product testing for conformity to declared technical standards

- Absolute functional certainty over time

- Doors “type approved” in compliance with M.D. 21 June 2004

- Products delivered with the documentation required by current regulations

Manufacturing technology

- Manufacturing in modern and functional facilities which employ the latest technologies to maintain high quality levels and product uniformity

- The entire production process – from raw materials to painted and packaged products – takes place inside Ninz’s own facilities, ensuring a 360 degree door control