Description

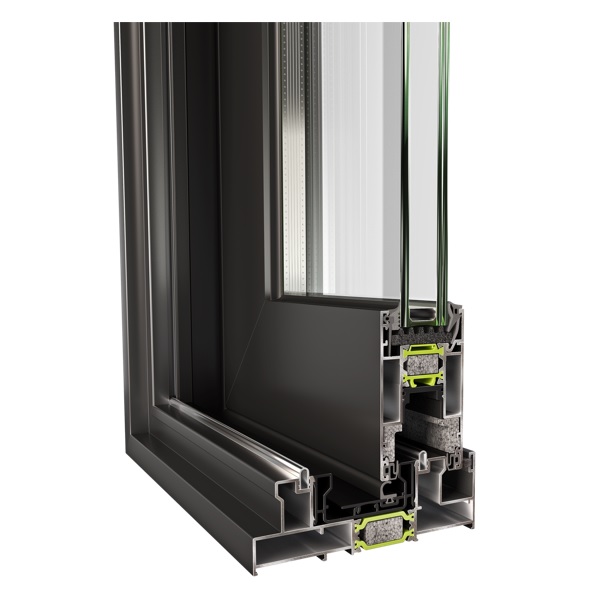

KEY SYSTEM FEATURES

– Use of stainless steel plate on the guides for smooth rolling.

– Design of profiles in straight lines.

– Possibility of installing a Lift & Slide mechanism.

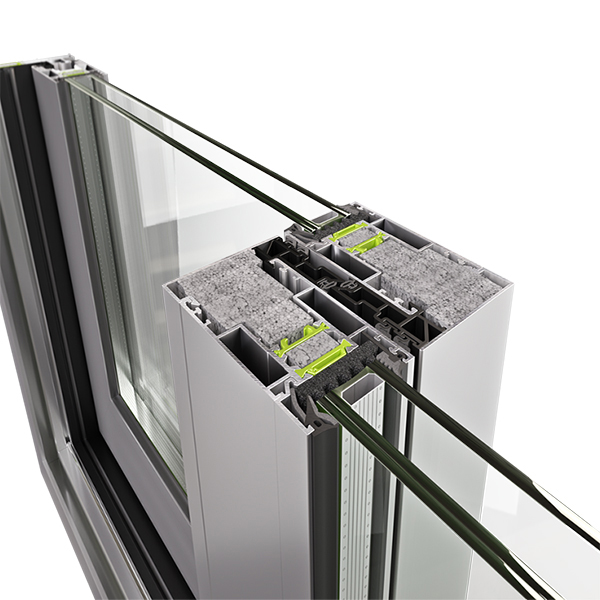

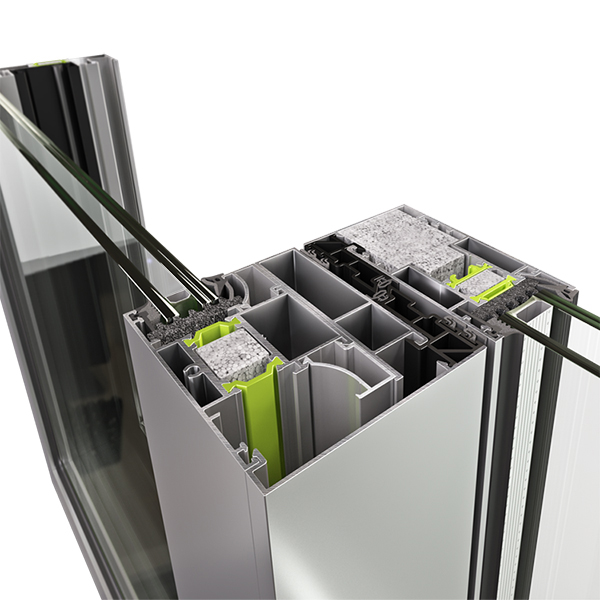

– Use of 24mm & 34mm polyamides for increased thermal insulation.

– Possibility of mounting multiple locking mechanisms.

– Split plastic (PVC) conductor cover for increased insulation and protection from water.

– Foam overlay pad (EPDM).

– Use of non-return valve for optimal drainage of the driver.

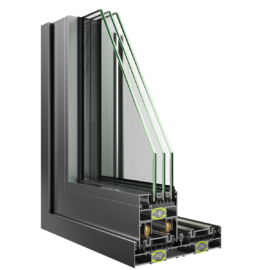

– Possibility of installing double or triple glazing up to 36mm for high levels of thermal insulation and sound insulation.

– Use of tubular rubber (EPDM) in the sheets for absolute waterproofing.

– Specially designed sheet addition (PVC) for the perfect fitting of the components.

– Use of additional sealing rubber on the bottom and side parts of the guide.

– Maximum thermal insulation using EPS graphite insulating material.

specifications

– Aluminum alloy: EN AW 6060 T66

– Hardness: 12 Webster

– Minimum paint thickness: 75μm

– Thickness of profiles: 1.4-1.8mm

– Dimensional tolerances according to: EN 12020-02

– Width of superimposed guide: 125mm

– Width of guide with fixed: 149mm

– Thickness of glass sheet: 50mm

– Thickness of sheet glazing of glass: 24-36mm

– Width of polyamides: 24 & 34mm

– Thermal transmittance factor of frame: Uf from 1.63 to 3.17 W/(m 2 K)

– Maximum sash dimension with raised mechanism (WxH): 2.0m x 2.7m

– Maximum sheet weight with raised mechanism: 200 Kgr

BUILDING TYPES

– Overlapping

– Lifting or simply sliding

– Single-layer-Double-layer with external fixed

– Composite constructions